Innovation Van Mourik Group “VMG Flaker”.

The Van MOURIK GROUP is familiar with the processes in the animal feed industry and the challenges faced by its clients and their customers. We know better than anyone that switching to new technologies and production methods is a risky decision. This does not mean that no developments take place. The feed market is moving. Society increasingly calls for improved animal welfare. Healthy ‘happy’ animals provide better quality products. Livestock therefore requires quality feed, customised solutions and alternatives to the traditional (compressed) compound feed.

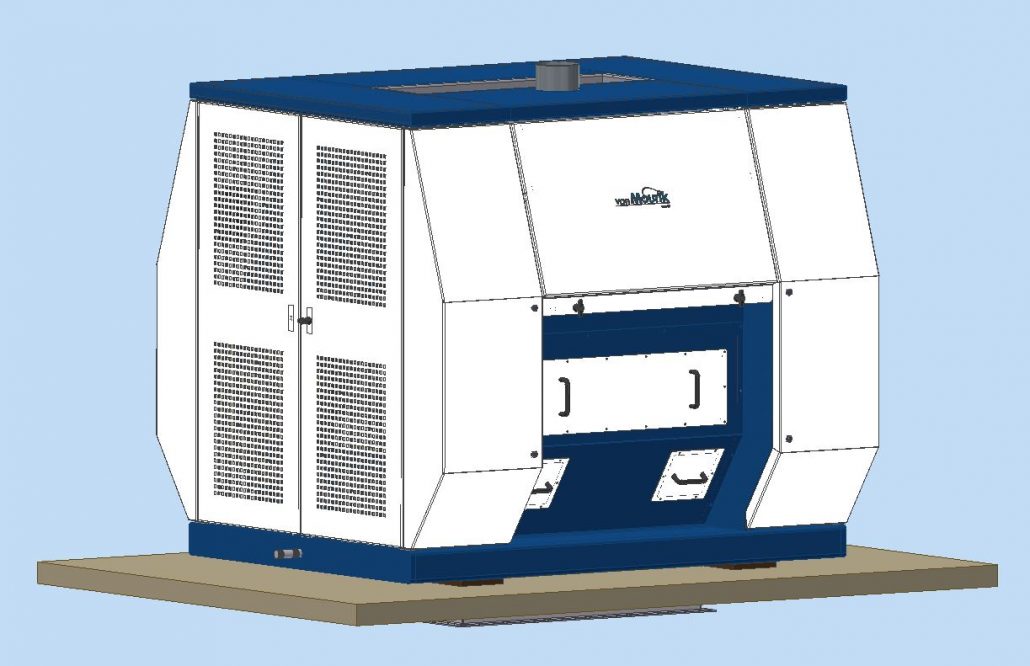

This increasing demand for responsible animal feed requires alternative forms of production and a flexible production process. Thanks to our years of experience, we can offer an attractive and innovative solution: the VMG Flaker with automatic roll adjustments.

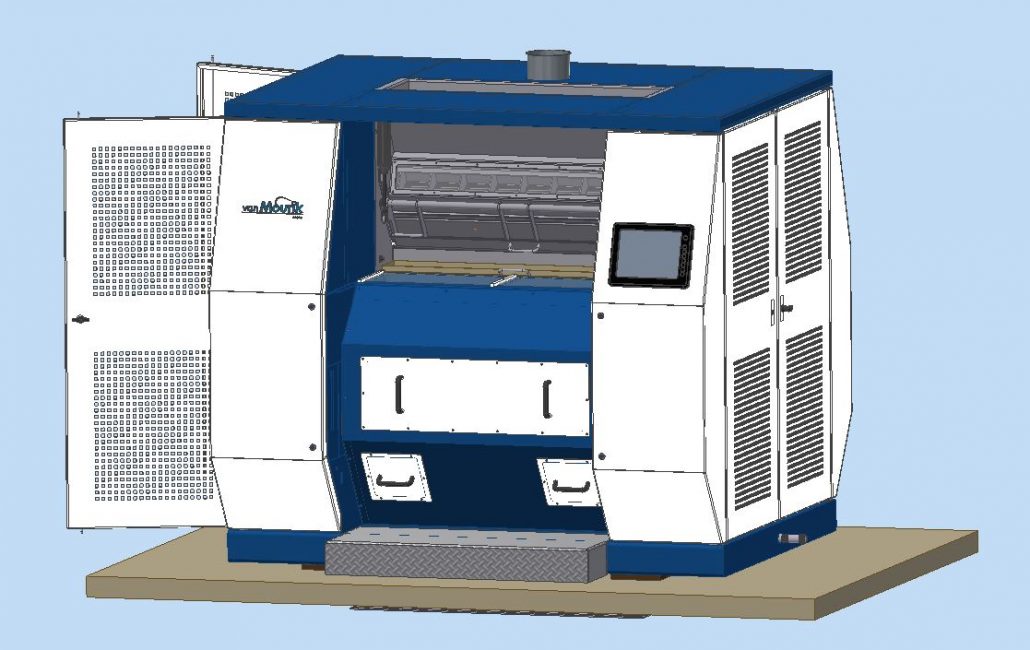

The VMG Flaker has been developed for processing of cereals and grains into flakes while adding heat and moisture. This production method makes it possible to offer an attractive alternative to various functions in the current production process such as grinding and pressing.

The VMG Flaker is an advanced production machine which does not only use little energy thanks to the use of modern technology, but is also silent and with limited dust emissions. This makes the investment particularly attractive and means – not unimportant – that the risks with respect to dust explosion and dust exposure are greatly reduced, resulting in a safe working environment.

The high capacity of the unit combined with limited floor space and easy integration into existing production lines ensure fast and optimum efficiency within your production process. Thanks to the automatic roll adjustments, the flake size can vary without halting the production process. This increases the flexibility in the production process and ensures that the production can be customised within the production process based on client need.

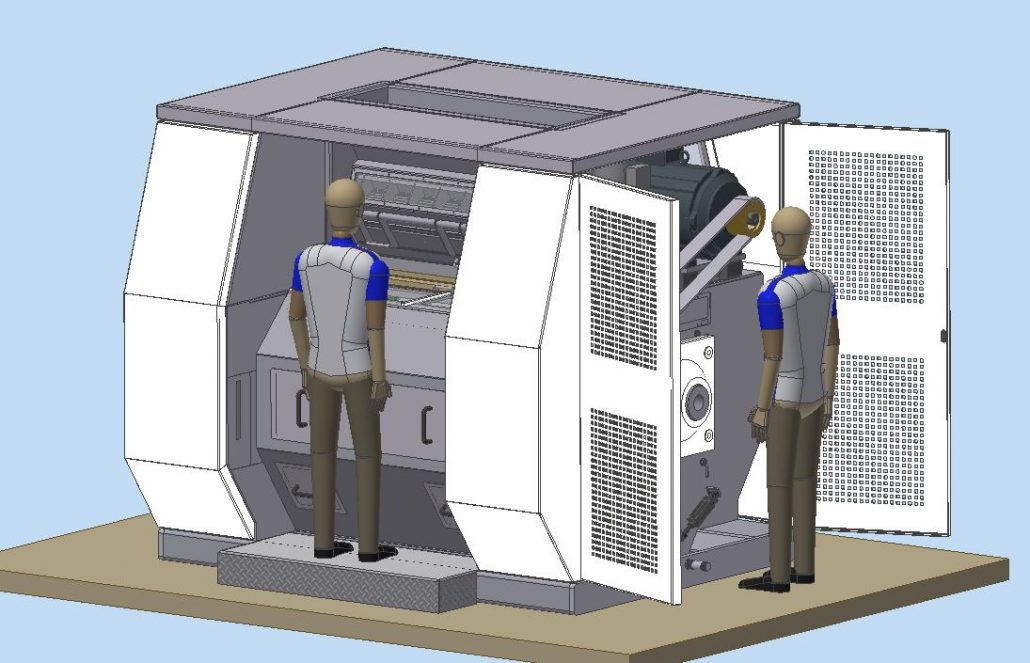

This new production method also results in less wear and consequently less maintenance and a longer service life of the machine. When developing the VMG Flaker, optimal cleaning and sampling with as little as possible downtime in the production process were the focus.

In addition to animal feed, the VMG Flaker is also perfectly suitable for extracting vegetable oils from oilseeds and field crops such as, for example, sunflower seeds, rape seeds, linseed, maize, soybean, palm oil, etc.

The benefits summarised:

- Your unique product with the quality you are used to in a different form. The VMG Flaker allows a completely different application while maintaining your existing recipes. Instead of compressed chunks, you can offer a granola or use the flakes as a semi-fabricated product in your range.

- Thanks to the process of breaking and flaking, the lead time of the product, and thus the production process, can be reduced significantly.

- The flexibility of your production process is increased: choosing between finished and semi-finished product is made easy. You can choose a process in which the flakes are delivered as a final product, or process them as a semi-finished product in your regular production process. ‘Custom’ production based on customer requirements is made simple.

- The unit can easily be placed in the existing production process.

- Using the VMG Flaker partly eliminates the process of grinding and pressing. This can save on energy and thus not only positively affect the costs, but also the CO2 footprint of your company.

- This new production method results in less wear and tear, resulting in less maintenance, less downtime and longer service life of the machine!

- Easily accessible for cleaning, sampling and maintenance.

As you expect from us, Van Mourik Group can provide you with the complete installation and commissioning. The maintenance of the production unit has been carefully considered in the design. The easy accessibility of installation and serviceability enable you to perform preventive maintenance in-house. Of course, you can also engage our specialised service and maintenance service for this.

The machine comes with a comprehensive user and maintenance manual. Of course, the VMG Flaker meets the Machinery Directive 2006/42/EC and has a CE label.